Recent Project Highlight: High Concrete

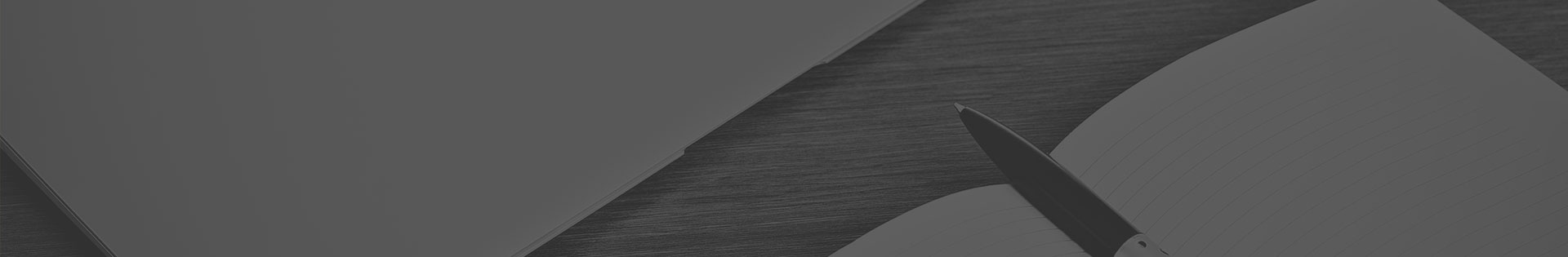

Concrete Plants, Inc. recently completed installation on a dust collection system for High Concrete’s sand-blasting operation in Denver, PA. The dust collector system was tied-in to their existing production facility with 60” galvanized flanged ducting. C&W Manufacturing supplied two 70,000CFM dust collectors, with dual 150HP blowers, providing 14,476 sq. ft. of filtration area. See the photos and details below for some more project highlights.

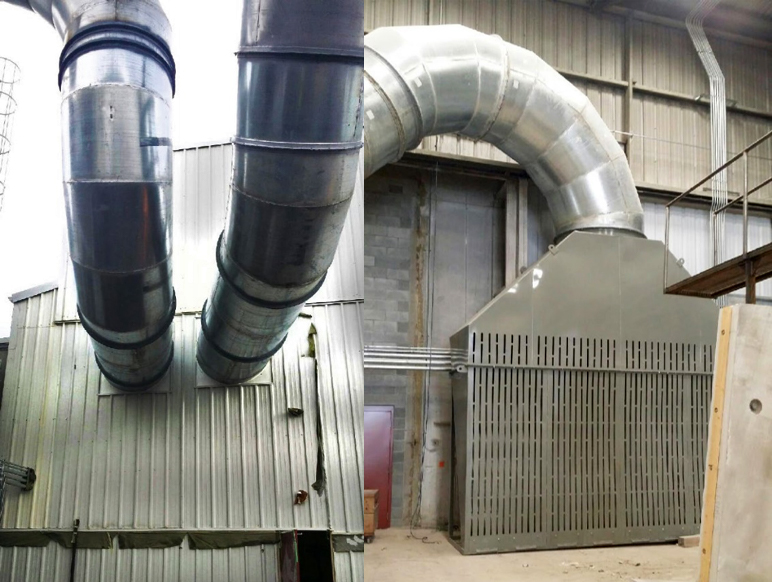

C&W supplied two (2) CP-70,000 Dust Collectors for High Concrete’s silica sand blasting operation.

Each CP-70,000 features:

- 14,476 Sq. Ft of Filtration Area

- Each collector has two 55 gallon barreldrops to collect dust for easy disposal

- 70,000 CFM with 150 HP Fan @ 8” W.C.

- 99.9% filtration efficiency

- 60” galvanized, flanged ducting

- 140 cartridges – 8” x 78” with tool-less filter media exchange for easy maintenance

- Dual pyramidal hoppers with high level indicators

- Dwyer Digihelic Gauge for cleaning of cartridges based on differential pressure measurement

Cat-walk connects the two collectors, accessed by a caged ladder. All platforms were designed to meet OSHA requirements.

Dual 60” heavy-gauge, ducting lines were retrofitted to tie in to the to the slotted side draft hoods. C&W Mfg. supplied two (2) slotted side draft hoods inside the 50’ wide 150’ long 36’ high building. Both feature top pyramidal inlets and draw air from one end of the building, to the collector, to purify the air inside the building.

C&W Manufacturing supplied two 150HP, one for each collector. Each fan includes a silencer with rain hood. Noise levels with the silencers installed are reduced to 85dba @ 10ft. in an open field.

C&W Manufacturing supplied two 150HP, one for each collector. Each fan includes a silencer with rain hood. Noise levels with the silencers installed are reduced to 85dba @ 10ft. in an open field.

Not Shown: Two banks of inlet air-powered louvers (at opposite end of building) allow airflow across the building interior when the dust collectors are in operation. A Dwyer digihelic gauge is installed on each collector, allowing the the systems’ automatic cartridge cleaning system to turn-on based on the differential pressure measurement. This way, the collector only the cleans the cartridges as-needed – extending the lifespan of filter media and conserving compressed air.

For more information on this project and others, contact your sales representative – or call our parts office at 717-351-1100.