CPI Completes New Precast Plant

Concrete Plants, Inc. recently finished the installation of a new precast concrete plant in Maine. For full plant specs and pictures see below. Contact our team today to find out more about the equipment, installation, and service we can offer.

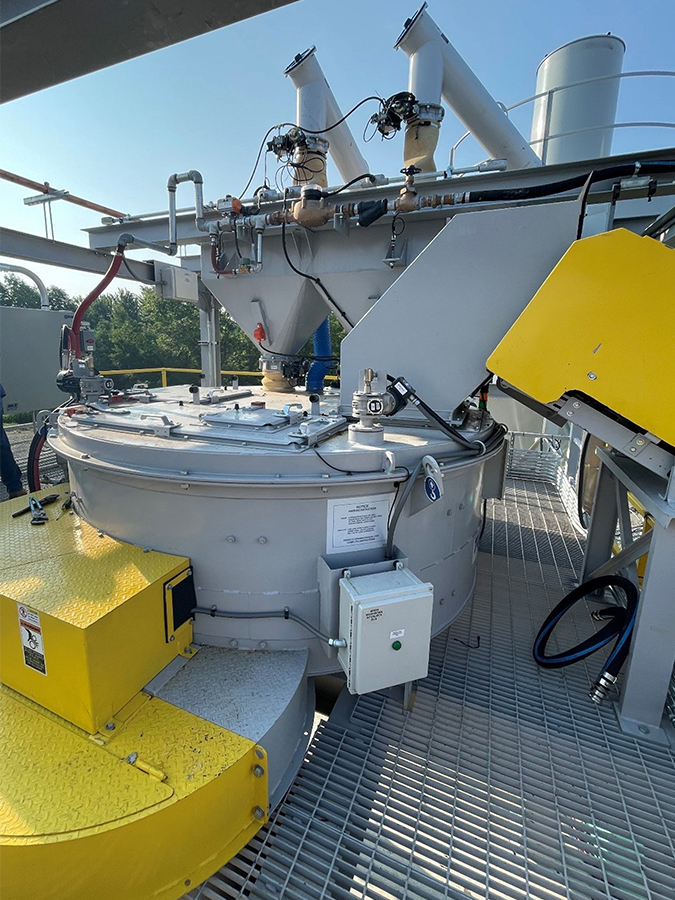

Mixer Systems Model 150 Turbin Mixer: 41 cubic ft. input capacity, with 50HP drive with planetary gear reducer mounted internally. 3/16″ Steel tank construction with 1/2″ AR floor liners and 3/8″ AR wall and well liners. Stationary radial water distribution system. Two (2) pneumatically operated discharge doors with lockable ball valves and flow controls. Mixer safety interlock system with E-stop push button, doors closed safety switches, and 10sec mixer start-up delay with audible/visible alarm.

Mixer Systems Auto-Washout System: 15HP Pump mounted on steel base, supplying three (3) rotary nozzles which clean in an oscillating, spherical spray pattern. Washer inlet and outlet assemblies. Supplies 13Gals per minute at 1600psi. Handheld high-pressure spray wand for final clean-out.

Cement Silos + Weigh Batchers: (2) Belgrade Steel Tank 50 ton cement silos (270bbl) with split-compartment cement weigh batcher (17 cubic ft. per compartment). Pneumatically operated butterfly valves. Externally mounted aeration pads with manifold. Manual shut-off emergency slide gate. Low-level and high-level indicator probes installed. 4″ Fill lines with installed anti-overfill system with alarm and pinch valves.

Screw Conveyors: (2) WAM 8″ X 22′-0″ screw conveyors with 11HP drive assemblies.

Agg Storage: Steel Systems Installations fabricated aggregate storage bins. 12′ X 14′ lip-mounted agg hoppers built from 1/4″ steel plate with bolt-in 1/4″ AR liners. Double-clamshell discharge gates with air cylinders and controls. Include (3) heavy-duty drive-over grizzlies.

Conveyors: 24″W weigh-belt conveyor on load-cells for accurate weighing of materials. 24″W incline conveyor. Loading skirt with rubber wipers. E-stop pull-cord switches and warning horns.

Automation: Mixer Systems E-150 Batch Control system. Color touch screen interface connected to a PLC. Auto and manual controls. Storage for up to 50 programmable mix designs. One-button start for fully-automated batching. Multi-level password protection on system. Automated jogging of agg gates for accurate weighing. Operator adjustable moisture calculation. Configurable batch sequence for aggregate materials. Alarm system on batching and mixing processes. On-screen maintenance monitor for batch plant. On-screen operators manual, diagnostics, and electrical schematics. Report printing. Remote batch data collection. Watt meter used as slump indicator. Hydronix moisture probe for accurate moisture monitoring.